7 Warning Signs Your Printing Machine Needs Spare Parts

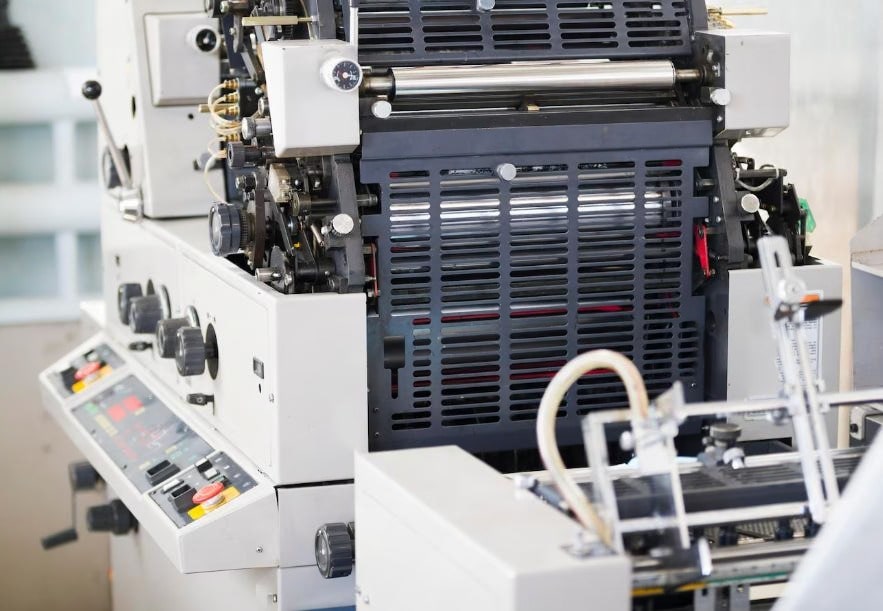

It is a busy device that your printing machine chugs on out day after day making your business a success with the documents, labels or marketing materials that you print. However, just as any item of equipment, printers do wear out. Understanding the signs before your printing machine gives out are some tips that may help you avoid expensive downtimes, low quality in printing and emergency repairs.

It usually takes time before most printing problems manifest themselves. Rather they grow by a gradual change of performance, or a change of print quality or unfamiliar sounds. By becoming aware of them and having the ability to observe them progressively, you will be able to perform people to have maintenance during times that suit you as opposed to failure when you need the printer the most.

This manual will take you through seven potential signs that tell you that your printing machine needs new spare parts and that it would help you to be fine with performance and set a longer operating life of your equipment.

Poor Print Quality Issues

Even the most elementary indicator of a need of the spare components in your printing machine manifest itself in its printed materials. When the documents that were once crisp to look at begin to look unprofessional, it is a time to check what some parts of it are breaking up.

Faded or Inconsistent Colors

The fading color usually represents that the toner cartridges, drum units or developer units will be worn out. In case the problem is not solved by replacing the toner, then, the problem is deeper in the printing mechanism. Developer units that assist in transferring toner to paper do wear out in time and lead to patchy or irregular color reproduction.

Streaks and Lines on Printed Pages

Vertical lines or streaks down your printed pages are likely an indication of damaged drum units, or dirty transfer rollers. Those elements are essential to design professional-like clean documents. Streaks that go in a horizontal direction may be a sign of fuser unit or paper feed problems.

Blurry or Smudged Text

Where the screen is fuzzy and smeared, a number of assemblies might be the problem. Fuser units or worn may not adequately bond toner to paper and old transfer belts may not exert enough pressure in printing. The problems are even noticeable when components get old and no longer very precise.

Unusual Noises During Operation

An efficient printing device works in a recognizable, smooth manner. This should alert you when you begin to hear some new or louder sounds, your printer is sending out a message to you.

Grinding or Scraping Sounds

The grinding sounds imply bad bearings, broken gears, and assemblies which are out of installation. These noises indicate that there is an inappropriate rubbing of metal parts against each other and this could result in a heavier damage when unresolved. Typical causes are by worn pickup rollers, broken drive gears or a dying motor assembly.

Squealing or High-Pitched Noises

High-pitched noise is usually caused by the worn belts, the failed motor or the dried-up places of lubrication. Specifically, transfer belts may get cracks or fallen tension and produce squealing sounds. Other noises that are similar are produced by motor bearings as they wear out.

Clicking or Rattling Sounds

Occasional clicking or rattling may be due to loose or damaged plastic parts, worn springs or bad sensors. These components could be working still though they have signs of wear which will eventually make them fail.

Paper Feeding Problems

Paper jamming is normal with any printer and when frequent feeding problems are experienced it is an indication of worn or damaged spare parts which must be replaced.

Frequent Paper Jams

Though jamming is normal; the jams experienced on a daily basis or more than once between print jobs are not a normal event. Old pickup rollers lose their grasp to the paper and paper runoff impairs the contamination of separation pads which allows multiple pieces to pass through at once. Smooth rollers or cracked rollers of the feed rollers cannot effectively take the paper through the printing way.

Paper Skewing or Misalignment

Incase pages are regularly produced at a crooked or misaligned status, the paper instructions system requires adjustment. These difficulties in alignment can be caused by worn out guide rails, damaged sensors on paper or failing registration assemblies. Uncontrolled misalignment can destroy the printer and leave unwanted materials to be used in paper printing.

Multiple Sheets Feeding Together

The term double feeding is used to describe this problem which is usually caused by our separation pads or pickup rollers which are dull and worn out. These parts are supposed to snatch only a single piece at a time, although, they will become less accurate over time.

Slow Printing Speeds

Slowing down of the print speeds is usually a sign that the internal elements are not keeping at the designed stage.

Contemporary printers are designed to print at a particular rate and hence considerable delays tend to arise out of worn motors, faulty sensors or plugged routes. The drive assemblies could have difficulty keeping correct timing and sensors would not work as fast to read paper position or print completed paper.

Other parts of the printer that tend to work slowly under the strains of age include the temperature-dependent parts such as the fuser units and vary longer to reach optimum operating temperatures or hold heat longer even in extended print jobs.

Error Messages and Warning Lights

The diagnostic system in your printer will also give you good information as to which spare parts require attention. These electronic threats should not be overlooked as they are set to avoid more severe destruction.

Component-Specific Error Codes

Most contemporary printers present certain fault codes that precisely point toward the failed components. The messages such as Replace Drum Unit:, Fuser Error, or Transfer Belt Warning, are well-guided information concerning the necessary spare parts to change. Ensure your printer is accompanied by the manual to enable you decipher these codes properly.

Persistent Warning Lights

When they are flashing or solid warning light and not clearing through normal troubleshooting it is reflected to be a hardware instead of a temporary trouble. These lights tend to go on when the sensors see that there is wear or faulty components.

Recurring Maintenance Messages

In a case when your printer keeps asking to be taken care of even after just being looked into, chances are that internal components are deteriorating than usual. This trend implies that the relevant spare parts should be replaced to regain functionality.

Visible Wear and Physical Damage

Visual inspections could allow finding out about the spare parts that have to be replaced before they lead to print quality problems or mechanical breakdowns.

Cracked or Damaged Plastic Components

The printer housings, the paper trays and the internal guides may crack up with time. Cosmetic but small damage may not be problematic on functionality, but cracks on parts that bear loads or components of precision parts can bring major issues.

Worn Rubber Components

Rubber materials used in the manufacturing of rollers, belts, and gaskets decay on their own accord after some time. Check rollers with smooth shiny surface, instead of being textured or belts with cracking or stretching.

Loose or Wobbly Parts

Part that are slack or movable in places they are not meant to move signifies worn mounting hardware, spring or bad parts. Such concerns tend to develop at a very fast rate once they have started.

Increased Maintenance Frequency

When you are forced to clean your printing machine, readjust or repair it, as frequently as it is not supposed to occur lie spare parts behind the problem.

Good printers have uniform performance between the routine maintenance. And when you get to the stage where you seem to spend hours cleaning paper paths, setting adjustments, and clearing minor jams, chances are that the real problem is worn moving parts and that they are going to require replacement and not repair.

This maintenance demand usually increases with time because adjusted parts receive greater stress due to the expenses of failed parts.

Taking Action When You Spot These Signs

The reason why you should identify these warning signs in time is that you have the benefit of scheduled repair instead of emergency work. Write down any problem that you notice and its frequency and conditions. This fact aids technicians determine quickly the kind of spare parts that your printing machine requires.

It is worth taking into consideration to make the most used spare parts be stored, at least important printers in the business. Products such as toner cartridges, drum units and paper feeder components can be required with short notice and are a major problem when they break down because they can have a significant effect on productivity.

These warning signs, together with routine maintenance schedules will ensure you get the best out of your printing equipment and at the same time keep the professional quality that your business requires.